Introducing Tuff Tube Transition's Tuff Tube Header Connection (TTHC)

(Tuff Tube Header Connection – TTHC)

US Patent and International Patent Pending

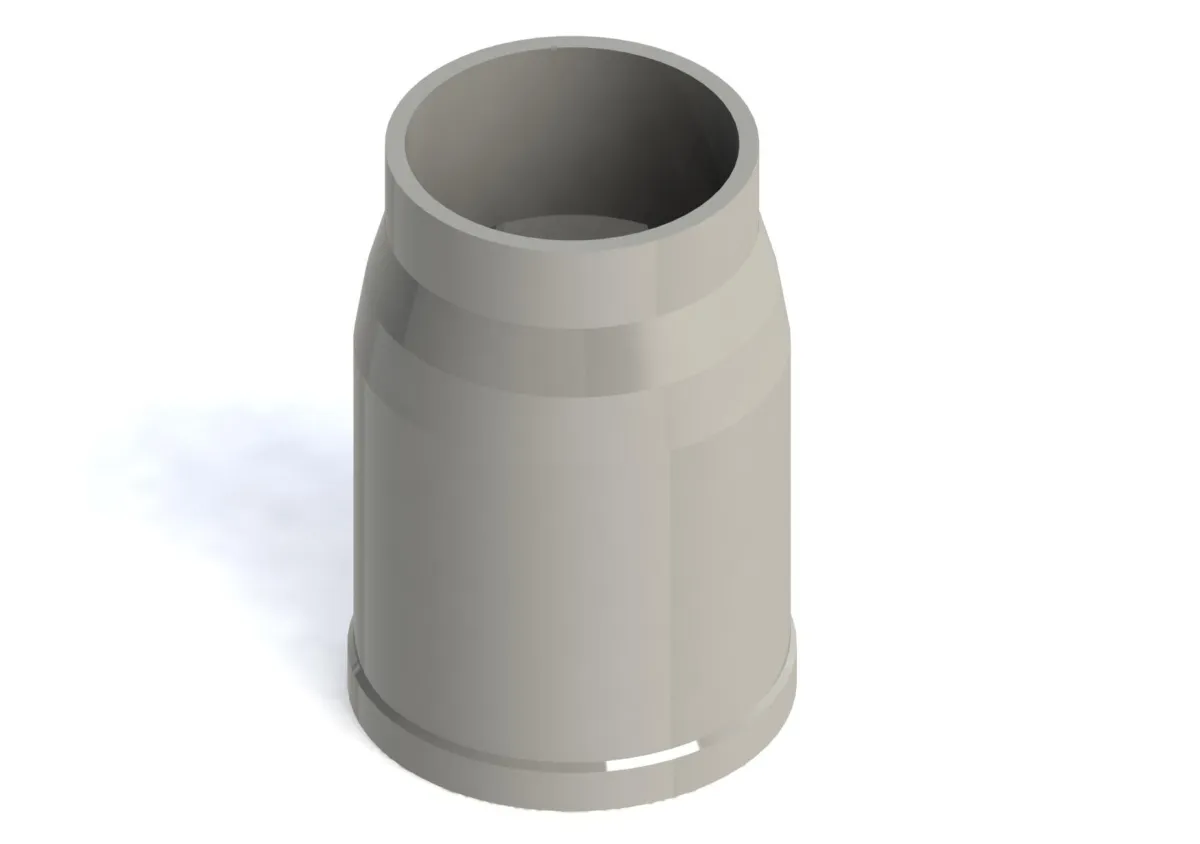

After years of development, Tuff Tube Transition has revolutionized the tube repair

process. Our cutting-edge technology addresses the root cause of most tube failures: the heat-

affected zone (HAZ) at the tube-to-header weld. Traditional repairs involve welding thin-walled

tubes to thick-walled headers, resulting in a massive thermal fatigue difference. This leads to

the tube pulling away from the header over time, especially at the weaker HAZ. Tuff Tube Transition significantly reduces this thermal fatigue gap, providing a stronger, more secure, and safer connection. Unlike traditional repairs, which require removing and replacing sections of tube and relying on imperfect purging, our solution eliminates the need for

butt welds and purging entirely. This not only ensures no oxidation occurs, but also drastically cuts down on repair time.

Tuff Tube Header Connection (TTHC)

Key Benefits of Tuff Tube Transition:

● No purging required: Say goodbye to the guesswork and risks of oxidation.

● Fast installation: Repairs can be completed in just a few hours, reducing downtime.

● Cost savings: Save annually in power plant maintenance and downtime.

● Stronger connection: Reduces thermal fatigue, ensuring long-lasting, secure repairs.

Ready to Upgrade Your Header Repairs?

Discover how TTHC system from Viking Vessel Services can improve your next project’s efficiency, safety, and cost-effectiveness. Whether you're dealing with critical repairs or planning ahead for future tube issues, TTHC offers unmatched reliability and performance.